How to reduce a bore?

What is we calling?

Many of you ask us this question.

It is simply a diameter of the hole of a mechanical part.

On discs or other circular polishing tools, it is the diameter of the tool attachment hole on the shaft or drive axle (a wheel, a disk or a grinding wheel).

You can arrive that you face particular bore dimensions depending on the diameter of the drive axis of your machine.

But no panic: it is quite possible to reduce the bore diameter of your disc hole, wheels and grinding wheels with simple mounting accessories that make it possible to perfectly adjust the bore of the hole of your tools to the drive axis.

Explanations:

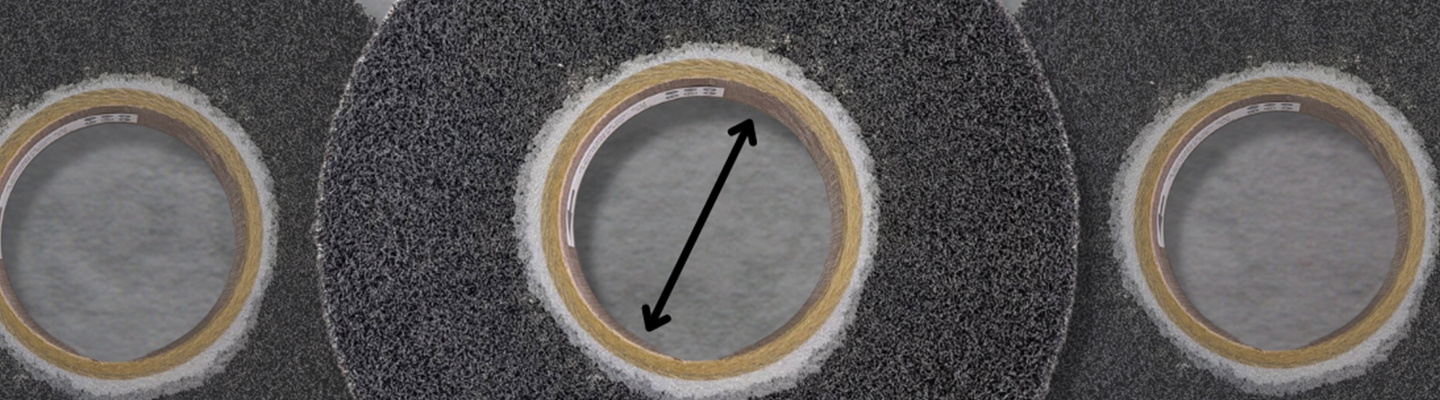

Polishing tools have attachment holes to rather common bores with a tendency to standardize.

At Sacille Spap, we propose 2 reduction systems Bore bores of the attachment holes of your disks that can be used individually or combined.

The centering flanges

Processive solutions, our polyethylene centering flanges (HDPE) shoulder reduces the bore of the mounting holes of your wheels and to obtain a perfect centering on the drive axle.

But how does it work?

Nothing simpler: In the first place, you must choose a flange whose shoulder is suitable for central drilling (bore) of your wheel.

The PEHD centering flanges are pierced with the most common diameters (25 mm, 32 mm or 35 mm), or even only pointed in their center to allow you to make the desired diameter mounting yourself.

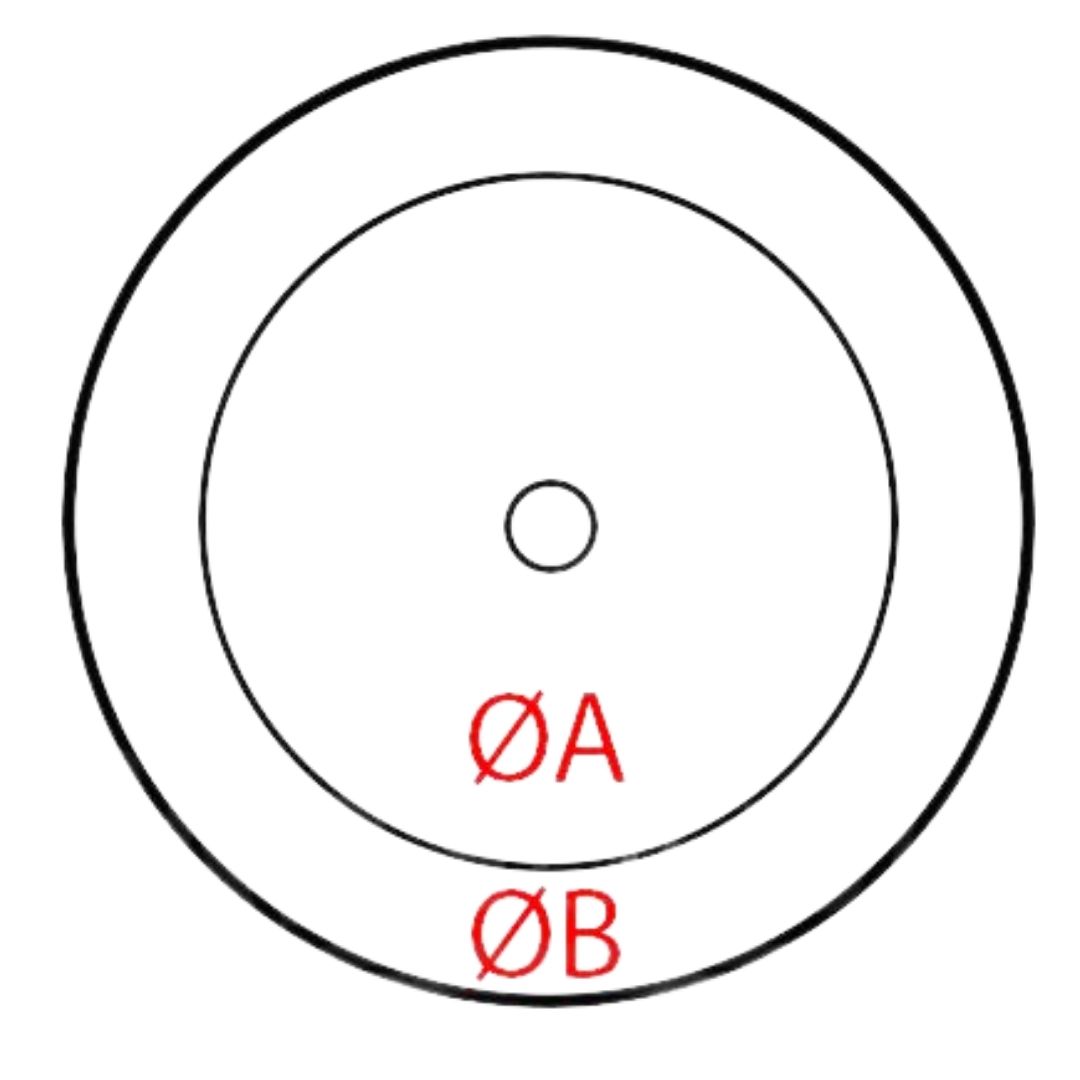

The role of the flange shoulder in diameter adapted to drilling your wheel is perfectly center and maintain, while its central bore of 25, 32 or 35 mm will allow mounting on an axis of drive of one of these diameters currents.

Let's take an example: You want to use A lamellar satin wheel of dimensions Ø 200 x 30 mm with a central bore of 76.2mm. You have to choose a shoulder flange of this same diameter (76.2mm Inner diameter Øa and 95mm of Øb outside diameter), but with a bore of 32 mm or 35 mm depending on the diameter of the axis of the drive shaft.

It will then be sufficient to proceed with the editing, as in the photo below.

Reduction rings

It sometimes happens and even quite frequently, that the drive axis of your machine does not match the bores of the wheels and discs available on the market and you want to use.

In this case, an operational and secure assembly can be obtained with plastic reduction rings, with or without collar.

These rings are available in a wide range of dimensions and can be used in combination With our PEHD centering flanges or even combined with each other Until obtain a bore perfectly adapted to the diameter of the drive axis.

The centering and discount flanges always come up by 2. It will be better to use as many standard reduction rings as necessary to reduce the bore of the tool (grinding wheel, drive) and ensure a good maintenance.

In this eventuality, the thickness of the standard rings may slightly exceed the thickness of the tool. It will then be necessary to decrease the thickness of a ring, to the band or to the grinding wheel, in order to obtain a thickness corresponding perfectly to the thickness of the tool or very slightly lower.

Practical examples:

- You have adapted a wheel satin wheel using of centering flanges and reduction of HDPE 32 mm bore but the drive shaft of your machine is 25 mm diameter. The best solution will be to put on each side of the flanges a collar reduction ring of Ø32 / 25.

- You want to use a brush Ø250 x 27 Bore 35 mm steel and the axis of your touret is 22 mm. In this case, the assembly can be carried out by inserting 2 standard rings Ø35 x 10 mm - Bore 22 mm with a 3second After reducing its thickness to the band or grinding wheel of 3 or 4 mm.

With Sprocket Spap, every problem finds its solution and our solutions solve all the problems.