What is a cutter backstand?

A Backstand is a Sander fixed abrasitic bandsstudents, unlike an electroportactive sander, and sometimes modular (depending on the model) for a procedure vertical or horizontal.

Used for a number of manual work, the backstand is a precious cutery ally for the realization of blades or the Sleeve shaping.

Generally equipped with a contact wheel, the cutter backstand offers a pleasant comfort of use and allows you to perform a precise work.

There are several models from the most basic at most sophisticated With, for example, a variable rotation speed or the ability to add accessories for complex shape work.

The benefits of the cutter backstand.

Whatever the model, a cutter backstand will make huge services to the workshop:

- Time saving For the formatting operations of parts, sanding and sharpening.

- Good master's degree for complex forms.

- Facilitates Sharpening operations.

- Allows you to perform a particularly neat work.

- Comfort of use for the operator.

- Security of use thanks to its design and accessories.

- Economical use Thanks to the longevity of the abrasive bands.

A considerable time saving at the workshop.

The time won To perform grinding or sanding operations is difficult to comparable with manual operations. Sanding with an electroportactive sander will also be much less fast and mastered as it will be necessary to fix the room repeatedly according to the area to work.

CAUTION However not to press the band too much to avoid the Blueing of metal parts Or all risks of burning more tender materials like wood.

To avoid any disappointment, it is advisable to use a suitable speed and a controlled gesture where the abrasive belt Remove the material by pressing moderately.

A beautiful mastery for the realization of pieces of shape.

As the cutter backstand is fixed, it is the user who will present the workpiece in the position he wants to machine the zone he wants. This allows the cutter to adapt his gesture to the shape to be made with, of course, all the necessary safety precautions.

Depending on the backstand model used, accessories Can be added as, for example, rollers of different diameters to achieve and work with hollow parts.

A perfect sharpening in a walk.

Cutlers particularly appreciate the use of a backstand for its speed and efficiency to achieve accurate blade or sharpening.

Beginners will be able to quickly acquire the "help"By helping the inclination capabilities of the work table for a sharpening at the right angle.

A particularly neat job.

Thanks to the Perfect mastery of the operator on his pieces, but also to the possibility of quickly changing the abrasive belt, the result obtained is particularly neat, sometimes without the need for finishing for little than the grain and the material of the band used either adapted to the work to be performed.

There are many types of abrasive tapes with different sizes of grains and the choice will be done Depending on the material to work and the desired result.

Maximum comfort of use.

By its design, the Cutelier Backstand offers a comfort of use Total, reinforced by inclination capacities, or even overthrow for the most sophisticated models. Thus, following the work to be made, the abrasive belt can be positioned vertically or horizontally.

The work table, usually reclining at the desired angle, allows you to perform regular and homogeneous series operations quickly.

A secure design.

The designers of cutter backstands did not leave the side of the operator safety.

Although it is necessary to take some precautions and wear protective equipment (gloves, glasses, etc.) The cutter backstand is equipped with protective housings, a generally tilting work table and optional accessories allowing the work of complex forms.

Economic use.

If a cutter backstand can represent a significant investment, its regular use remains nevertheless economic thanks to the longevity of the abrasive bands.

Several rules will be respected to achieve real savings and get a perfect performance:

- Use quality abrasive tapes.

- Use the type of abrasive tapes adapted to the material to work.

- Adjust the speed of rotation according to the work to be made.

Depending on the type of material worked, the choice of powdering of abrasive strips (closed, open, semi-open) will be decisive to avoid floating and too fast wear.

To extend the duration of use of your abrasive bands, do not hesitate to use our declining sticks regularly.

Professional backstands.

With his experience with the cutlers, SPAP Soucille Markets professional backstands Goset, a well-known European builder in cutting media.

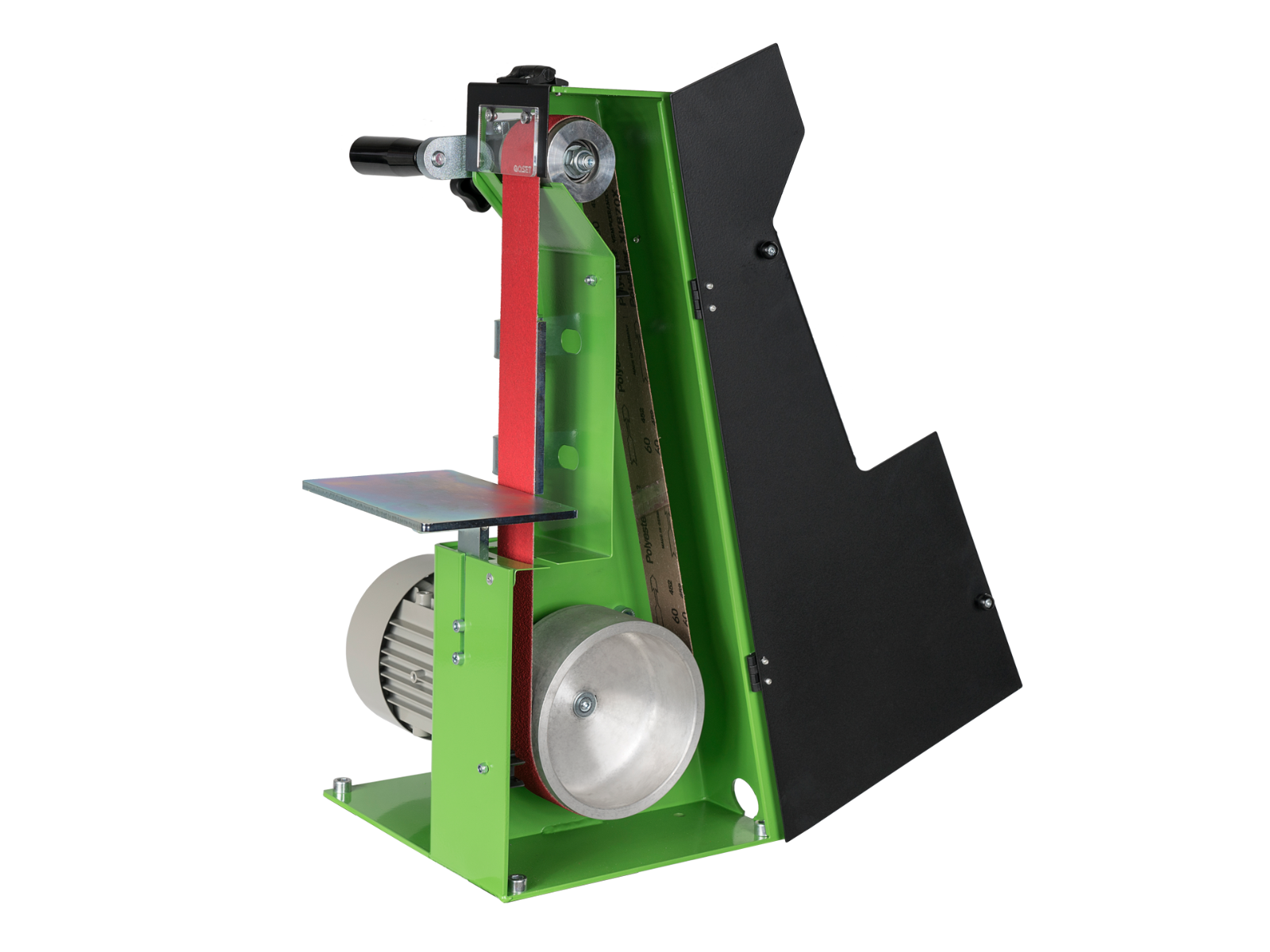

The model G10, space-cumbersome and economical, is perfect for a beginner cutter. Its powerful engine, its robust design make it a certain asset to the workshop.

Models G10 use abrasive bands of 1220 x 50 mm.

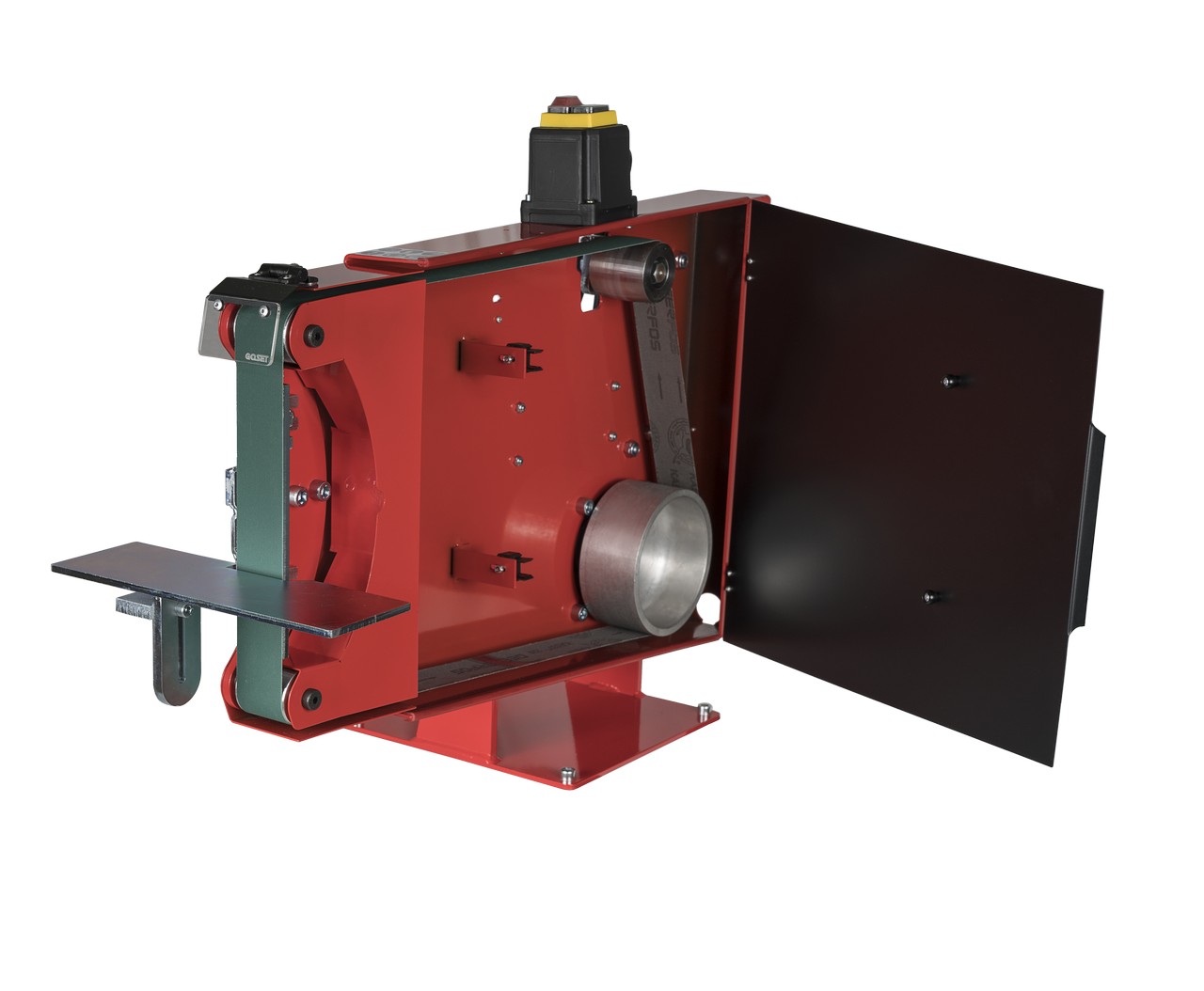

Models G20 and G20 Pro, just as robust, can be used in vertical and horizontal position.

Their design allows you to use a series of optional accessories for making particular machining (rollers, contact wheels, magnetic fixing grinding system).

Backstands G20 use abrasive bands of 2000 x 50 mm.

© Copyright 3801 - Total or partial reproduction forbidden without authorization from Sproid spa.