Nylon discs

Nylon discs

Nylon ventilated discs

UNIVERSAL GLUE

MEDIUM DISC - LAPIDARY DISC HOLDER

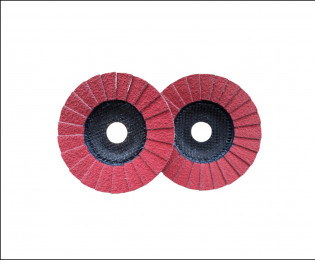

Ceramic flap discs flat Ø125 mm

SUPPORT PLATE fibre sanding disc Ø5 in. M14

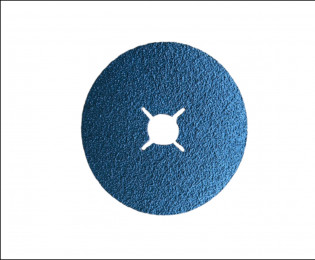

VSM ceramic ABRASIVE DISC fiber ACTIROX

Zirconium ABRASIVE DISCS ZF713 fiber support

VSM XF870 ceramic fiber ABRASIVE DISCS

Zirconium flap discs flat Ø125 mm

Lapidary abrasive discs - KP520E

Self-tagging abrasive discs - KP510

Abrasive discs Corundum KP131

The ever-increasing complexity of the parts to be processed and the appearance of new advanced materials (alloyed steels, stainless steels, composite materials, resins, etc.) are permanent challenges for abrasive disc manufacturers such as VSM Abrasive.

Difficulty of access to the areas to be worked, hardness, toughness or, on the contrary, flexibility and resistance of the materials have led the Research and Development departments of the manufacturers to hitherto unequalled levels of perfection capable of meeting the challenges of today and tomorrow in terms of performance, cost reduction and sustainable development.

The traditional "sandpaper", although still in use, has given rise to a multitude of new technologies for both the backing and bonding materials and the abrasive grains themselves.

The substrates have become ultra-resistant papers, cotton or polyester cloths and even latex.

Binders, often with ultra-secret chemical formulas, are essentially resins that are particularly effective in ensuring the abrasive grains hold, but can also be lubricants or anti-fouling and anti-dust.

The abrasives themselves have largely become synthetic and, consequently, much more efficient in their structures and homogeneous in their grain sizes.

Flint and corundum are now outperformed by aluminium oxide, zirconium, silicon carbide and ceramics to name but a few.

The distribution of grains (the powdering of the supports), while it may have been random in the past, is now perfectly mastered to become applied, structured, open, closed or semi-closed and other advanced technologies.

Technological and technical developments that allow the user to make considerable gains in competitiveness and in the quality of the surface treatments obtained.

Simple abrasive discs for large material removals or flap abrasive discs for more precision and a perfect finish, SPAP Soucille offers a wide range of abrasive discs from Ø125 to 400mm (Ø4.92 to 15.7in).

SPAP Soucille offers no less than 140 references of abrasive discs, of which more than 70 are in permanent stock and available immediately. If you do not find the one you are looking for, do not hesitate to contact our team.

Self-screwing, self-gripping, flap, fibre or lapidary: the right solution for every challenge! The sanding discs offered by SPAP Soucille come in as many shapes and materials as the areas to be worked on require. You are bound to find a disc that meets your expectations!

The sanding discs are adapted to the material to be worked on. Whether they are made of impregnated nylon or loaded with abrasives, sanding discs cover a wide range of grain sizes and contain particularly high-performance abrasives (zirconium, ceramic, alumina aloxite, silicon carbide, etc.).

Copyright 3801 - Reproduction in whole or in part without permission from SPAP SOUCILLE is prohibited.

Opt for our secure 3D secure payment system, Paypal or bank transfer.

Secure shipping in France in 72H, packaging adapted to the products.

We are at your disposal at 04 73 80 67 45 Monday to Tuesday from 9h to 12h and from 14h to 18h / Friday from 8h to 12h and from 14h to 17h

For any order placed before 13h your parcel is sent the same day